Machining Services

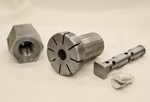

Comprehensive Milling & Machining Services

Advantage’s machining division is separated into several specialized areas. Each area focuses on key aspects needed to provide competitive pricing, superior quality and on time delivery. We quote parts complete, including most types of plating, inspection, SPC, PPAP and even assembly operations. Advantage also specializes in the machining of castings and forgings, with a network of suppliers across the country. We support JIT and Kanban deliveries to our customers as needed.

- CNC Milling and Turning

- Engineering Services

- Advanced Programming and Modeling Software

- Product Design

- Rapid Prototyping

- Computerized Inspection Equipment

- Manual Machining and Welding

- Post Processing and Assembly

- Full PPAP Capabilities

- Project Management & Development

Medium to High Volume Production:

Advantage is equipped with twin spindle, twin turret machines equipped with bar loaders which aid in reducing cycle time and costs due to the reduction in operations needed to complete a part. Utilizing quick changeovers allows us to decrease our lead times and maintain on time deliveries, while keeping lower inventory levels. Upon receiving blanket orders, we carry finished product inventories based on customer min/max stocking levels. This allows us to deliver products within 24 hours or receiving a release for delivery.

CNC Low Volume and Prototypes:

Whether using Mazatrol conversational programming right at the machine or 3D modeling/programming software in our engineering department, we are able to produce low volume orders quickly and cost effectively, even at single piece prototype levels. With support from our tool room, engineering staff and fabrication department, we are able to machine weldments, fixturing and prototype precision components.

Tool Room:

Our tool room provides gauging, fixturing and quick turn around prototypes.

Equipment List:

- 3 & 4 Axis Mazak CNC Machining Center (3)

- Largest VMC envelope size: Y=20″, X=44″, Z=20″

- Mazak CNC Turning Centers (5)

- Hardinge Single Spindle Lathes (4)

- OKK VMC with Pallet System

- Hardinge Autoloader with Gantry load/unload robots

- Twin Turrets & Twin Spindles (4)

- Sunnen Hone – Production Honing

- Turning with Live Tooling

- Pallet Shuttles

- Sub Spindles

- Bar Feeders

- Manual lathes, drill presses, milling machines, surface grinders

- Automatic cut-off saws, band saws (3)

- Gantry and Boom Cranes support material handling requirements

- Programmable CMM